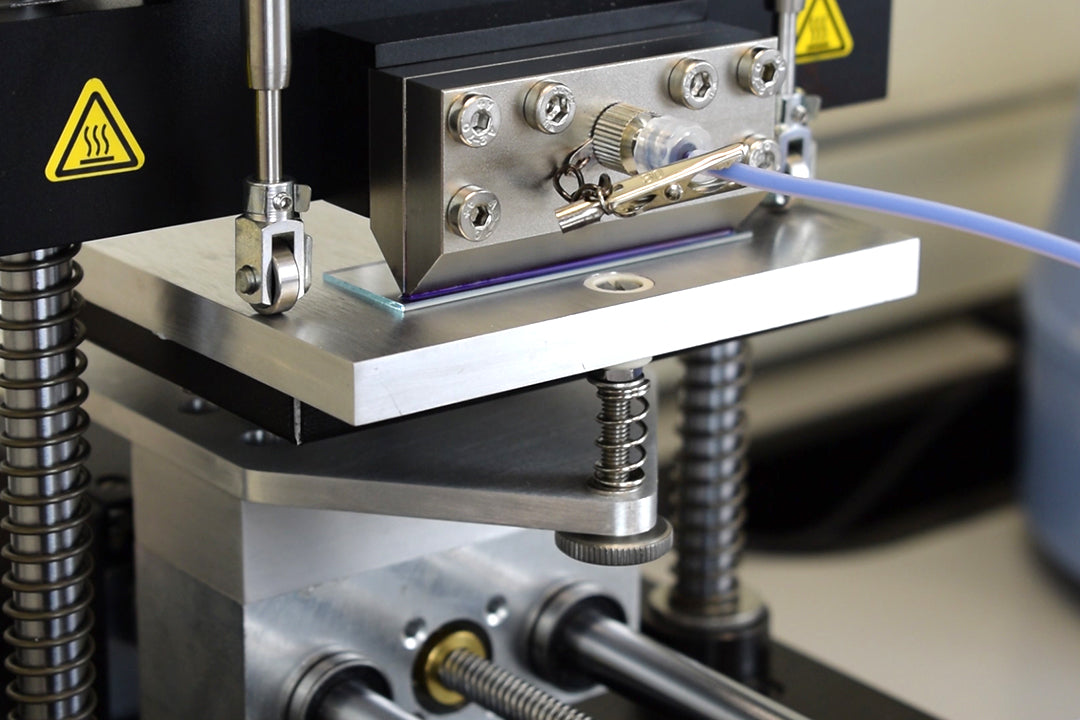

Design, Manufacture and Sales of Slot Coating Dies and patch coaters. Slot die coating technology is a method in which the coating liquid is supplied into the slot die and shaped into a wide and uniform film to deposit on a moving substrate. The technology has a wide variety of applications and is considered to be an extremely powerful means for the production of advanced optical-electronic products. The technology can be extended to simultaneous multi-layered coating for specific products. Many prominent companies that provide slot dies are good at machining and polishing metals, but the most critical issue for making a good slot die is the full understanding of the physical properties of all types of coating solutions, such as fluid rheology, evaporation rates and so on. WCC has extensive experience on managing various types of coating solutions and sound fundamental understanding on the rheological properties of coating solutions. The slot die designed and manufactured based on WCC's unique experience is cost-effective and can operate with high efficiency. WCC can also make flexible and versatile patch coaters for customers to make samples piece-by-piece up to 500mm wide. WCC promises satisfactory after service on related coating problems. |

Equipment

The equipment of the R&D centre varies, since it is kept up-to-date through constant retrofits, replacements and our own new developments. The Coatema R&D centre boasts unrivalled flexibility and a unique range of applications. It now also offers digital testing.

Design, Manufacture and Sales of Slot Coating Dies and patch coaters. Slot die coating technology is a method in which the coating liquid is supplied into the slot die and shaped into a wide and uniform film to deposit on a moving substrate. Slot die coating hot melt adhesives requires specialist systems to suit the specific requirements. Universal Converting Equipment is able to offer a range of slot die coating systems developed by Universal Adhesive Systems, ITW Dynatec and other manufacturers of slot dies.

Here you can see an overview of the current laboratory, pilot and production plants used at the Coatema R&D centre at present:

Test Solution Coater

Coating system

Doctor blade

Slot die system

Commabar

Working width

DIN A4 (297 x 210 mm)

Operating speed

0 – 4 m/min.

Power supply

230 V, 50 Hz

Design

IP54

Dimensions (LxWxH)

1,100 mm x 580 mm x 530 mm

PDF download presentation

Coatema – The Test Solution

Test Solution R2R

Coating systems

Doctor blade

Slot die system

Commabar

Working width

100 mm

Roller width

150 mm

Operating speed

0.1 – 5 m/min.

Working direction

unidirectional

Winding diameter

max. 150 mm

Power supply

400 V, 50 Hz AC, CWW-32 A, 5P, 6h

Design

IP54

Compressed air

min. 6 bar

Dimensions (LxWxH)

2,200 mm x 1,000 mm x 2,000 mm

PDF download product brochure

Coatema Test Solution

PDF downloadpresentation

Coatema – The Test Solution

Easycoater

Coating systems

Doctor blade

Slot die system

Screen printing

Working width

max. 360 mm x 360 mm

Operating speed

ca. 0.4 – 4 m/min.

Dryer temperature

max. 120°C

Design

IP54 / EEx

Dimensions (LxWxH)

1,920 mm x 1,220 mm x 1,920 mm

Smartcoater

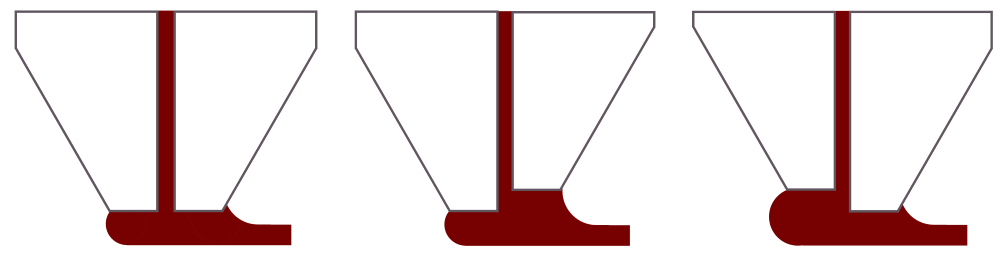

Slot Die Coating Head Design

Coating systems

Knife system

Slot die system

Rotary screen system

Engraved roller system

Micro roller system

Dipping system (Foulard)

Working width

300 mm

Roller width

350 mm

Operating speed

0.1 – 10.0 m/min.

Tensile strength

10 – 250 N

Dryer

Hot air

Dryer temperature

max. 235°C

Exhaust Air / Consumption of nitrogen atmosphere

325 m3/h

Design

Atex / IP54

Dimensions (LxWxH)

5,500 mm x 1,050 mm x 1,855 mm

Basecoater

Coating systems

Slot die system

Double-sided-slot die system

Dipping system (Foulard)

2-roller system

Working width

300 mm

Roller width

350 mm

Operating speed

0.1 – 5 m/min.

Tensile strength

25 – 250 N

Dryer

Hot air

Dryer temperature

max. 235°C

Dimensions (LxWxH)

5,100 mm x 1,350 mm x 3,000 mm

Click&CoatTM

Coating systems

Slot die system

Knife system

Kisscoater

Engraved roller system

3-roller system

Screen printing

Powder scattering system

Working width

500 mm

Roller width

600 mm

Operating speed

0.1 – 2 m/min.

Tensile strength

10 – 250 N

Dryer

Hot air (UV, IR on demand)

Dryer temperature

RT – 235 °C

Exhausting air

ca. 1,500 m3/h

Design

Atex / IP54

Dimensions (LxWxH)

depends on combination

Linecoater

Slot Die Coating Designs

Coating system

Reverse Commabar

Working width

700 mm

Roller width

800 mm

Operating speed

3 – 30 m/min

Tensile strength

100 – 1.000 N

Dryer temperature

max. 180°C

Air circulation

5.000 m3/h per section

Exhaust air

5.000 m3/h per section

Dimensions (LxWxH)

19,000 mm x 2,500 mm x 2,600 mm

Universal Coater

Coating systems

2 x 3 Roller system (for under and upper side)

1 x Slot die system

1 x Knife system

Working width

500 mm

Roller width

600 mm

Operating speed

1.0 – 30 m/min.

Tensile strength

75 – 3,500 N

Dryer

1) Floating dryer inert, Exhaust: 2,500 m³/h, Circulating air: 2500 m³/h

2) Conventional hot air dryer, Exhaust: 2,500 m³/h

Dryer temperature

1) Floating dryer inert: 140 °C

2) Conventional hot air dryer: 235 °C

Air circulation

2 x 6.000 m3/h

Exhaust air / Consumption of nitrogen atmosphere

270 m3/h

Design

Partially Atex / IP54

Dimensions (LxWxH)

19,000 mm x 3,500 mm x 2,700 mm

Deskcoater

Coating systems

Intermittend coating

Working width

500 mm

Roller width

600 mm

Operating speed

0.2 – 2 m/min.

Tensile strength

25 – 250 N

Dryer

Hot air

Dryer temperature

235 °C

Exhaust

ca. 2.500 m3/h

Design

IP54 / EEx

Dimensions (LxWxH)

4,250 mm x 1,600 mm x 3,100 mm

Dissolver

Coating system

Doctor blade

Slot die system

Commabar

Working width

DIN A4 (297 x 210 mm)

Operating speed

0 – 4 m/min.

Power supply

230 V, 50 Hz

Design

IP54

Dimensions (LxWxH)

1,100 mm x 580 mm x 530 mm

PDF download presentation

Coatema – The Test Solution

Test Solution R2R

Coating systems

Doctor blade

Slot die system

Commabar

Working width

100 mm

Roller width

150 mm

Operating speed

0.1 – 5 m/min.

Working direction

unidirectional

Winding diameter

max. 150 mm

Power supply

400 V, 50 Hz AC, CWW-32 A, 5P, 6h

Design

IP54

Compressed air

min. 6 bar

Dimensions (LxWxH)

2,200 mm x 1,000 mm x 2,000 mm

PDF download product brochure

Coatema Test Solution

PDF downloadpresentation

Coatema – The Test Solution

Easycoater

Coating systems

Doctor blade

Slot die system

Screen printing

Working width

max. 360 mm x 360 mm

Operating speed

ca. 0.4 – 4 m/min.

Dryer temperature

max. 120°C

Design

IP54 / EEx

Dimensions (LxWxH)

1,920 mm x 1,220 mm x 1,920 mm

Smartcoater

Slot Die Coating Head Design

Coating systems

Knife system

Slot die system

Rotary screen system

Engraved roller system

Micro roller system

Dipping system (Foulard)

Working width

300 mm

Roller width

350 mm

Operating speed

0.1 – 10.0 m/min.

Tensile strength

10 – 250 N

Dryer

Hot air

Dryer temperature

max. 235°C

Exhaust Air / Consumption of nitrogen atmosphere

325 m3/h

Design

Atex / IP54

Dimensions (LxWxH)

5,500 mm x 1,050 mm x 1,855 mm

Basecoater

Coating systems

Slot die system

Double-sided-slot die system

Dipping system (Foulard)

2-roller system

Working width

300 mm

Roller width

350 mm

Operating speed

0.1 – 5 m/min.

Tensile strength

25 – 250 N

Dryer

Hot air

Dryer temperature

max. 235°C

Dimensions (LxWxH)

5,100 mm x 1,350 mm x 3,000 mm

Click&CoatTM

Coating systems

Slot die system

Knife system

Kisscoater

Engraved roller system

3-roller system

Screen printing

Powder scattering system

Working width

500 mm

Roller width

600 mm

Operating speed

0.1 – 2 m/min.

Tensile strength

10 – 250 N

Dryer

Hot air (UV, IR on demand)

Dryer temperature

RT – 235 °C

Exhausting air

ca. 1,500 m3/h

Design

Atex / IP54

Dimensions (LxWxH)

depends on combination

Linecoater

Slot Die Coating Designs

Coating system

Reverse Commabar

Working width

700 mm

Roller width

800 mm

Operating speed

3 – 30 m/min

Tensile strength

100 – 1.000 N

Dryer temperature

max. 180°C

Air circulation

5.000 m3/h per section

Exhaust air

5.000 m3/h per section

Dimensions (LxWxH)

19,000 mm x 2,500 mm x 2,600 mm

Universal Coater

Coating systems

2 x 3 Roller system (for under and upper side)

1 x Slot die system

1 x Knife system

Working width

500 mm

Roller width

600 mm

Operating speed

1.0 – 30 m/min.

Tensile strength

75 – 3,500 N

Dryer

1) Floating dryer inert, Exhaust: 2,500 m³/h, Circulating air: 2500 m³/h

2) Conventional hot air dryer, Exhaust: 2,500 m³/h

Dryer temperature

1) Floating dryer inert: 140 °C

2) Conventional hot air dryer: 235 °C

Air circulation

2 x 6.000 m3/h

Exhaust air / Consumption of nitrogen atmosphere

270 m3/h

Design

Partially Atex / IP54

Dimensions (LxWxH)

19,000 mm x 3,500 mm x 2,700 mm

Deskcoater

Coating systems

Intermittend coating

Working width

500 mm

Roller width

600 mm

Operating speed

0.2 – 2 m/min.

Tensile strength

25 – 250 N

Dryer

Hot air

Dryer temperature

235 °C

Exhaust

ca. 2.500 m3/h

Design

IP54 / EEx

Dimensions (LxWxH)

4,250 mm x 1,600 mm x 3,100 mm

Dissolver

Capacity

20 liters

Operating speed

650 – 3,000 r.p.m.

Side scraper

inklusive

Container

single wall / doule wall

Weight

420 kg

Dimensions (LxWxH)

1,220 mm x 1,100 mm x 920 mm